Nylon (Ethilon, Dermalon) Of all the nonabsorbable suture materials, monofilament nylon (Ethilon, Dermalon) is used most commonly for superficial closure of skin (see Table 8-2).

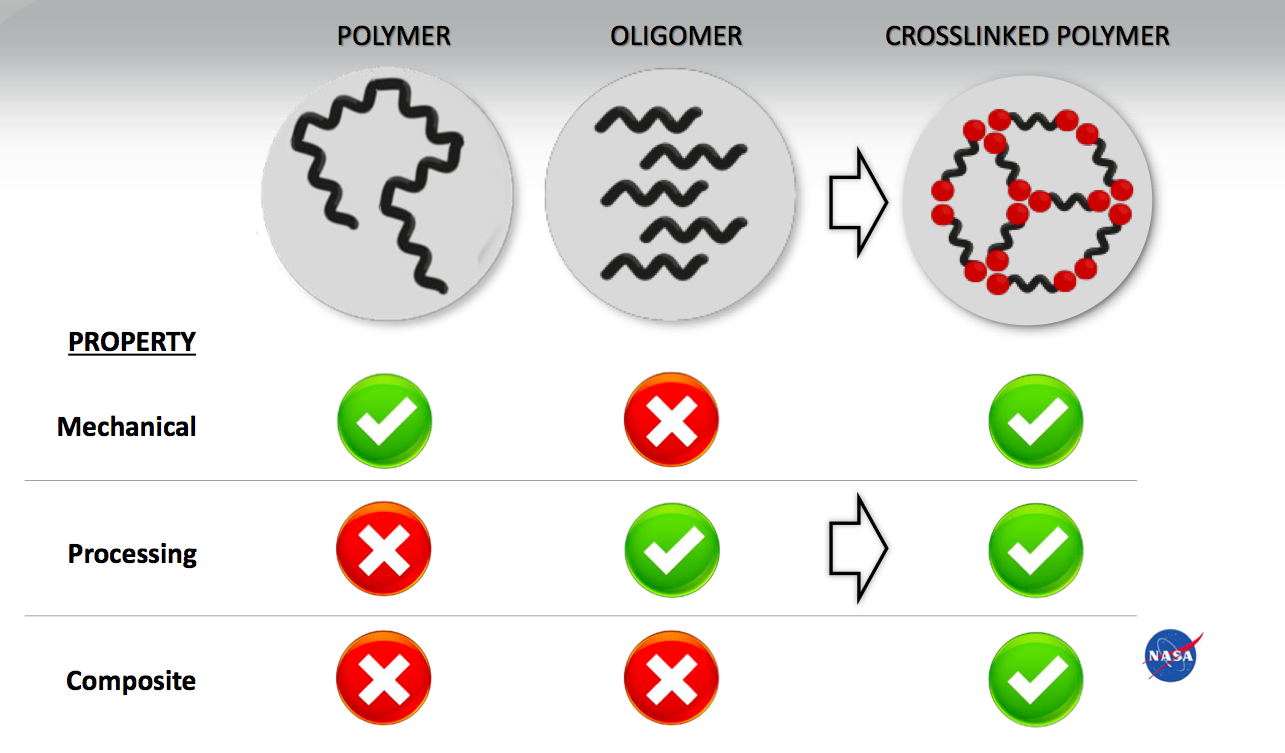

Introduction to the chemical reactions that produce polymers.

Conclusions – It is difficult to find the true composition of SV products. Manufacturers have mentioned two resins (nylon and polyethylene) that are used in their SV plastics, but have been unwilling to disclose the full formulations and additives.

UV/Visible Light Curing Adhesives, Light Curing Systems, and Dispensing Equipment. Dymax Corporation is a leading manufacturer of advanced light-curable adhesives, coatings, oligomers, light-curing equipment, and fluid dispense systems that work together to optimize assembly processes.

Manufacturer of SABIC 318CN Linear Low Density Polyethylene for Wire & Cable, SABIC 324CN Linear Low Density Polyethylene for Wire & Cable, SABIC 518N Linear Low Density Polyethylene for Blown Film, SABIC 6318B Linear Low Density Polyethylene for

1 Coatings Product Guide Table of Contents Technology Product Name Page Water-based Coatings PureKote™ 2 Water-based Print Receptive Topcoats PureKote™ 3-4

Oligomer molecule: A molecule of intermediate relative molecular mass, the structure of which essentially comprises a small plurality of units derived, actually or conceptually, from molecules of lower relative molecular mass.

Nylon 6 or polycaprolactam is a polymer developed by Paul Schlack at IG Farben to reproduce the properties of nylon 6,6 without violating the patent on its production. (Around the same time, Kohei Hoshino at Toray also succeeded in synthesizing nylon 6.)

Explains process of making nylon. This page is all about how to make nylon. We’re telling you this as if you can’t read the title for yourself.

Industrial organic chemicals are those 100 or so organic compounds produced in the United States in quantities ranging from millions of pounds to billions of pounds per year.